Hello all, I could use a little help

I have an LR5 that all of a sudden the suspension will not raise the vehicle. After doing a little searching here I found a thread that talks about the possibility of the suspension compressor not working. I looked on you tube and found an amazing video of a mechanic showing you how to replace the compressor here is the link

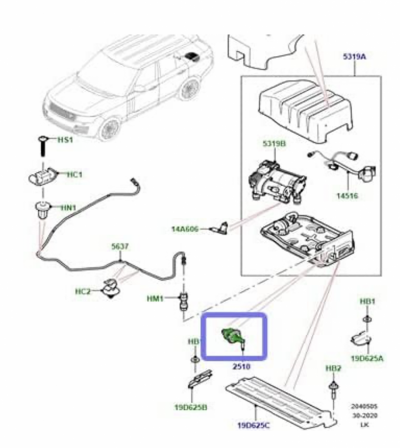

I took out the compressor and drilled out the rivets from the cover so that the compressor was exposed, I put back the compressor and conected it and turned on the rover. I immediately saw what the issue was. The culprit is the Dryer Valve when the compressor turned on you could see and hear a massive air leak through the Dryer Valve. You do not have to buy the entire compressor, you can simply purchase the Dryer Valve, remove the rivets and reinstall it. Cost was $75 on amazon this is the part number from Land Rover LR140035.

So I reinstalled everything turned on the Rover and the it started to fill the lines with air and the suspension raised the Rover.

The issue that I am having is that the compressor keeps on pushing air through the line and the air attachment point snaps off and the SUV goes down again.

Is this happening because the computer needs to be reset and it is not recognizing sufficient air in the lines?

Any help will be greatly appreciated. THX

I have attached the images of my compressor opened and also of the leak you can clearly see it. I also attached images of the parts diagram and Dryer Unit

I have an LR5 that all of a sudden the suspension will not raise the vehicle. After doing a little searching here I found a thread that talks about the possibility of the suspension compressor not working. I looked on you tube and found an amazing video of a mechanic showing you how to replace the compressor here is the link

So I reinstalled everything turned on the Rover and the it started to fill the lines with air and the suspension raised the Rover.

The issue that I am having is that the compressor keeps on pushing air through the line and the air attachment point snaps off and the SUV goes down again.

Is this happening because the computer needs to be reset and it is not recognizing sufficient air in the lines?

Any help will be greatly appreciated. THX

I have attached the images of my compressor opened and also of the leak you can clearly see it. I also attached images of the parts diagram and Dryer Unit